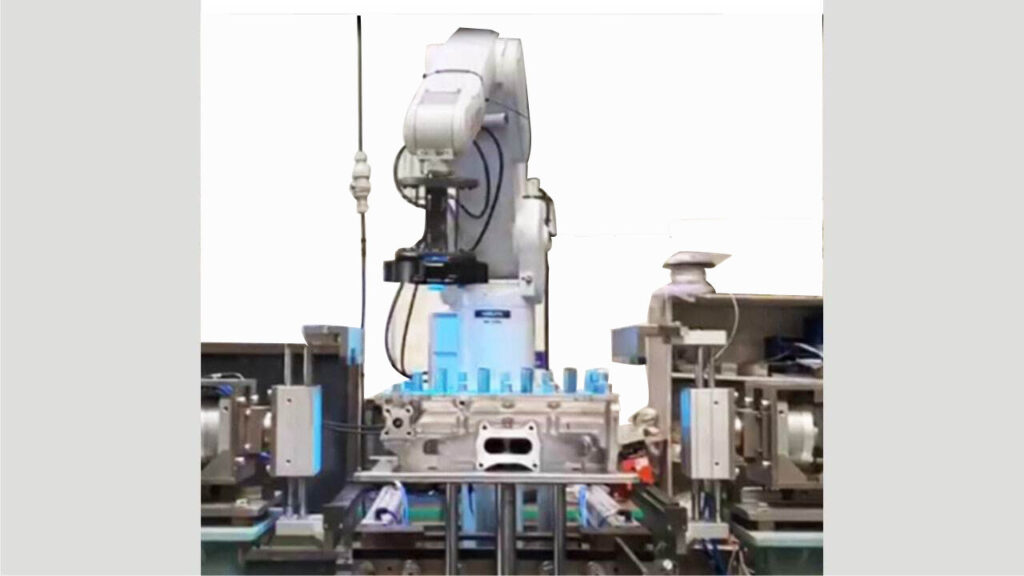

Vision Inspection Systems with Peripherals

Vision inspection solution for checking

- Missing Components In the Assembly

- Misalignment

- Dimenional Measurements

- Sorting

- Good And Bad Analysis

- Print Verification, Bar Code Reading

- Character Reading

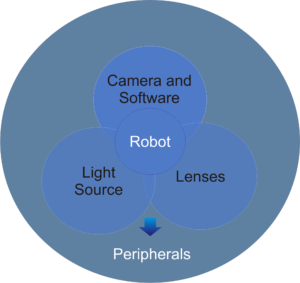

Vision solutions can be provided with Banner / Keyence / Cognex cameras

Vision Sensor – A self contained camera with controller. It requires no PC to run the inspection once the programming is completed.

The software is capable of matching patterns, counting, measuring, grey scale reading, barcode reading and character reading. Multiple inspection files can be stored in controller and can be called for inspection with a supporting PLC programming.

Light Source – Variety of colour in light source, light filters and strobe light are also offered as per application.

Lenses – C mount lenses, megapixel lenses, lenses with focal lock and telecentric lenses are used as per the requirement of a particular application.

Complete I/O systems for component handling provided as per requirement of the applications